Introduction to Laminated Woven Polypropylene (PP) Bags Product Category

Laminated woven polypropylene (PP) bags have gained significant traction across multiple industries, offering a durable, versatile, and eco-friendly alternative to traditional plastic packaging. These bags are constructed from woven polypropylene threads, which are then laminated with a plastic film for added strength, waterproofing, and enhanced durability. This combination of woven fabric and lamination gives laminated woven PP bags their distinct advantages, making them a popular choice in sectors such as agriculture, construction, retail, and more. In today’s sustainability-conscious market, these reusable and recyclable bags present an attractive packaging solution.

1. Exceptional Durability and Strength

The standout feature of laminated woven PP bags is their exceptional durability. Polypropylene is a robust material known for its high tensile strength, meaning these bags can carry heavy loads without tearing, stretching, or losing their structural integrity. The weaving process further enhances this strength, creating a fabric that can handle the rigors of transportation, whether for bulk goods like grains, cement, or other construction materials.

The lamination layer not only adds extra strength but also provides additional protection from moisture, making these bags water-resistant. This means that laminated woven PP bags can withstand exposure to rain or humidity, which is crucial for items that need to remain dry or be stored in varying environmental conditions.

2. Water-Resistant and Weatherproof

Another key benefit of laminated woven PP bags is their ability to protect contents from moisture, dirt, and other environmental factors. The lamination on these bags acts as a protective barrier, making them highly resistant to water and UV light. This feature is particularly important for industries such as agriculture, where products like seeds, fertilizers, and animal feed need to stay dry and free from contaminants. Additionally, the waterproof quality makes them suitable for outdoor storage and long-distance transportation in different weather conditions.

3. Lightweight and Portable

Despite their heavy-duty construction, laminated woven PP bags are surprisingly lightweight. This makes them easy to handle, carry, and transport, even when filled with bulky or heavy items. The lightweight nature of the material also reduces shipping costs, which is an important consideration for businesses that deal with high volumes of products. The portability of these bags, combined with their durability, makes them an ideal packaging solution for industries that require large-scale transportation or storage.

4. Customizable and Versatile Design

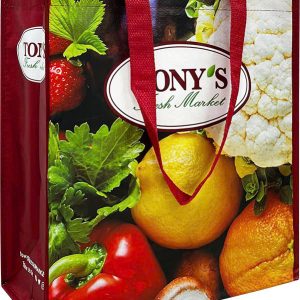

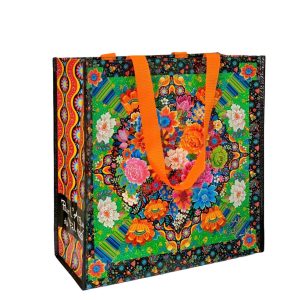

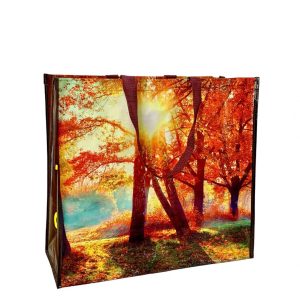

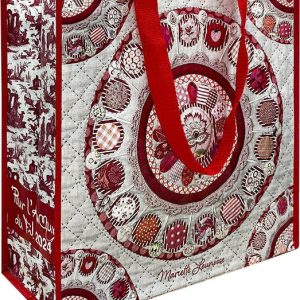

One of the most appealing aspects of laminated woven PP bags is their high level of customization. Businesses can print vibrant, full-color designs, logos, or product information directly onto the laminated surface. This makes these bags an effective branding tool, as the lamination helps preserve the clarity and brightness of the printed designs, ensuring that logos and graphics remain eye-catching even after repeated use.

Laminated woven PP bags come in a wide variety of shapes, sizes, and colors, catering to the specific needs of different industries. From small retail shopping bags to large bulk storage sacks, these bags can be tailored to meet various customer requirements. Additionally, their versatility extends to different closure options, such as zippers, Velcro, or drawstrings, depending on the product or application.

5. Eco-Friendly and Reusable

While laminated woven PP bags are made from plastic materials, they offer several eco-friendly advantages compared to traditional single-use plastics. These bags are designed for long-term use, meaning they can be reused multiple times, reducing the need for disposable packaging. Additionally, polypropylene is recyclable, so at the end of the bag’s life cycle, it can be processed into new products, minimizing its impact on the environment.

Many businesses are adopting laminated woven PP bags as part of their sustainability initiatives. The bags' reusability helps reduce the overall consumption of plastic, and because they are lightweight, they contribute to lower carbon emissions during transportation. In this way, laminated woven PP bags align with both economic and environmental objectives, making them a responsible choice for companies looking to reduce their environmental footprint.

6. Cost-Effective Solution

In addition to being eco-friendly, laminated woven PP bags are highly cost-effective. Their durability and long lifespan mean that businesses and consumers save money by not needing to replace them frequently. For companies that handle bulk goods, the reusable nature of these bags translates into lower packaging costs over time. Additionally, their lightweight nature reduces shipping expenses, offering an economical solution for businesses looking to optimize both cost and functionality.

Compared to more traditional packaging materials like paper, fabric, or single-use plastic, laminated woven PP bags offer a lower cost per use, making them an attractive option for industries with high-volume packaging needs. Whether used for industrial storage or retail purposes, these bags provide excellent value for money, thanks to their strength, reusability, and customizability.

7. Wide Range of Applications

Laminated woven PP bags are incredibly versatile and find applications across various industries. In agriculture, they are used for packaging grains, seeds, and animal feed. In the construction industry, they are ideal for storing cement, sand, or gravel. Retailers use smaller versions of these bags as reusable shopping bags, and they can also be used for promotional purposes, thanks to their customizability. Furthermore, laminated woven PP bags are widely used in the packaging of food products, chemicals, and other industrial goods, demonstrating their broad applicability across different sectors.

In summary, laminated woven polypropylene bags are a superior packaging solution that combines durability, water resistance, eco-friendliness, and cost-effectiveness. Their strength and versatility make them suitable for a wide range of industries, while their lightweight and customizable design offers a practical and attractive option for businesses seeking reusable, high-performance packaging.